The 3 pillars of innovative toolmaking

The 3 pillars of innovative toolmaking

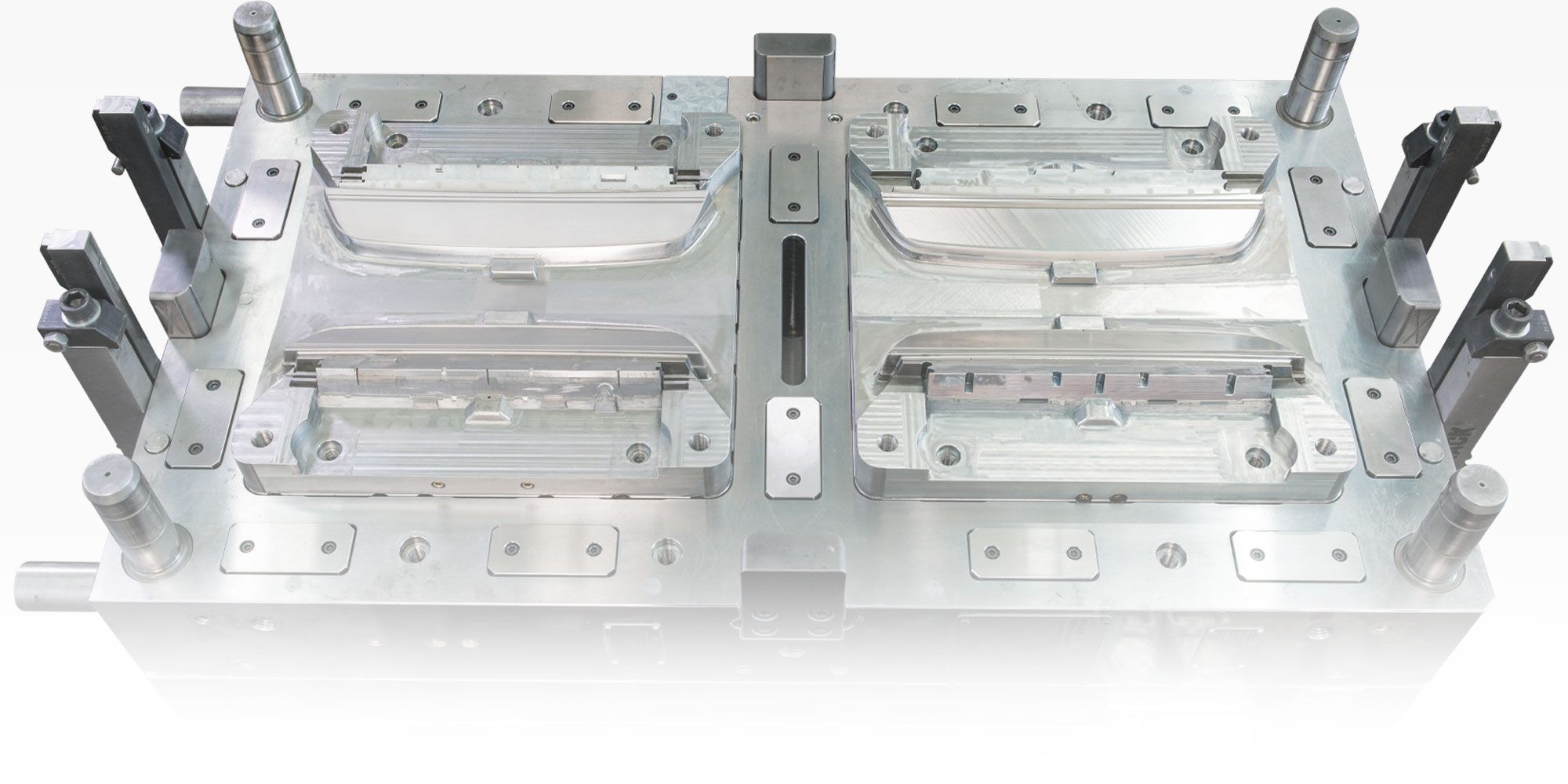

Pillar 3 of innovative toolmaking

Our in-house technical center enables tools to be tested directly on site.

It is also possible to carry out various samples/tests on behalf of customers and, if necessary, to produce small series.

Technical capacities:

-

2K/3K injection molding machines with

320–500 t clamping force -

Removal option using 6-axis robots

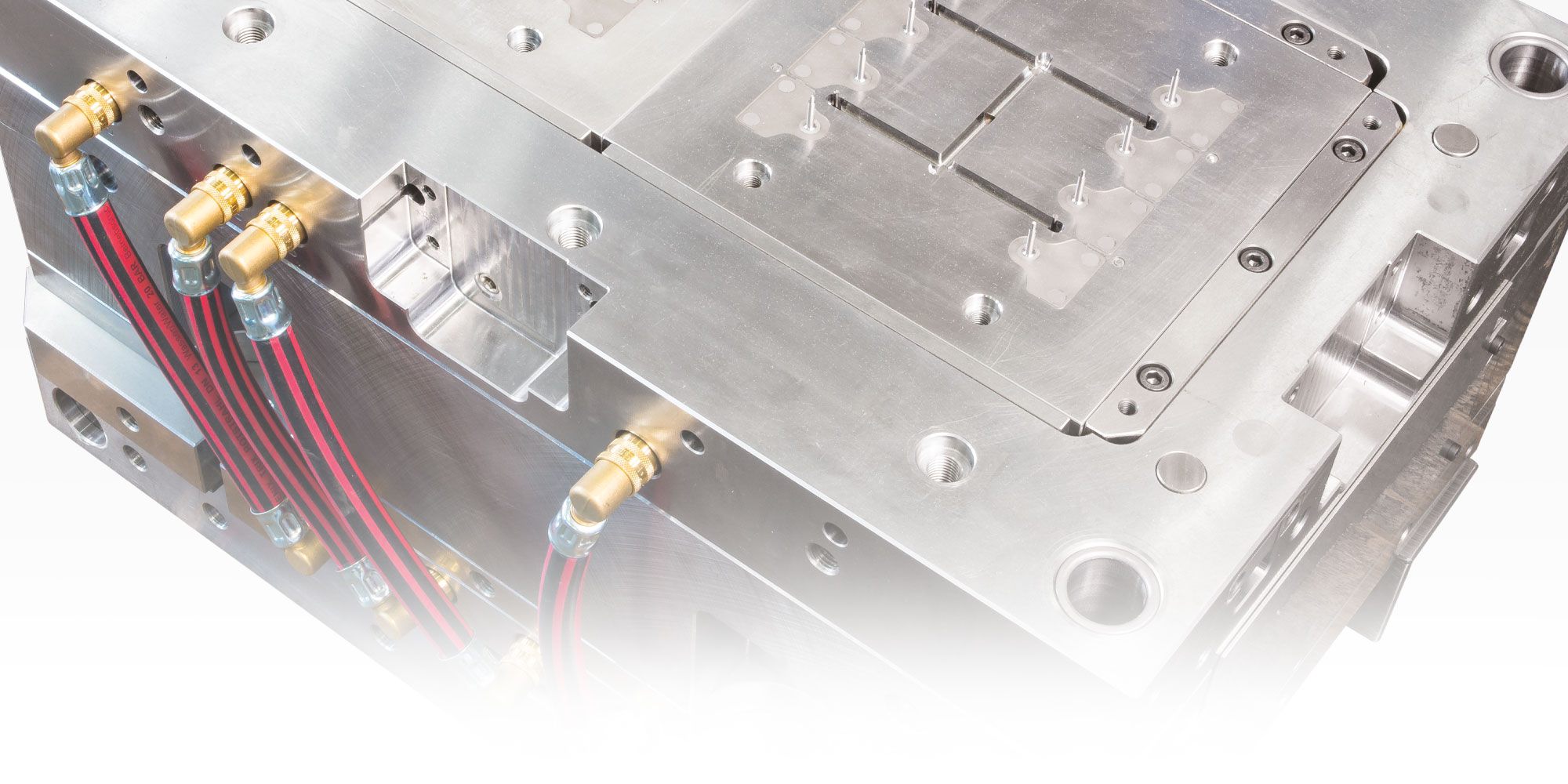

Quality assurance

All processes are integrated into our quality management system according to DIN EN ISO 9001.

In our workflows we use:

-

Toolmaking-specific production planning and control system

-

electronic order processing

-

automatic inventory reporting systems

CT scan with GOM Inspect professional

Example alignments

The GOM 3D software includes all standard alignment functions. These include: RPS alignment, hierarchical alignment based on geometric elements, alignment in a local coordinate system via reference points, and various best-fit methods such as global and local best-fit. Additionally, customer-specific alignments, for example for turbine blades such as balanced beam or equalized nested, can be performed.

Certification

-

We place great emphasis on optimization and are constantly working to improve our workflows.

-

To meet constantly growing demands, we undergo regular certification.