The 3 pillars of innovative toolmaking

The 3 pillars of innovative toolmaking

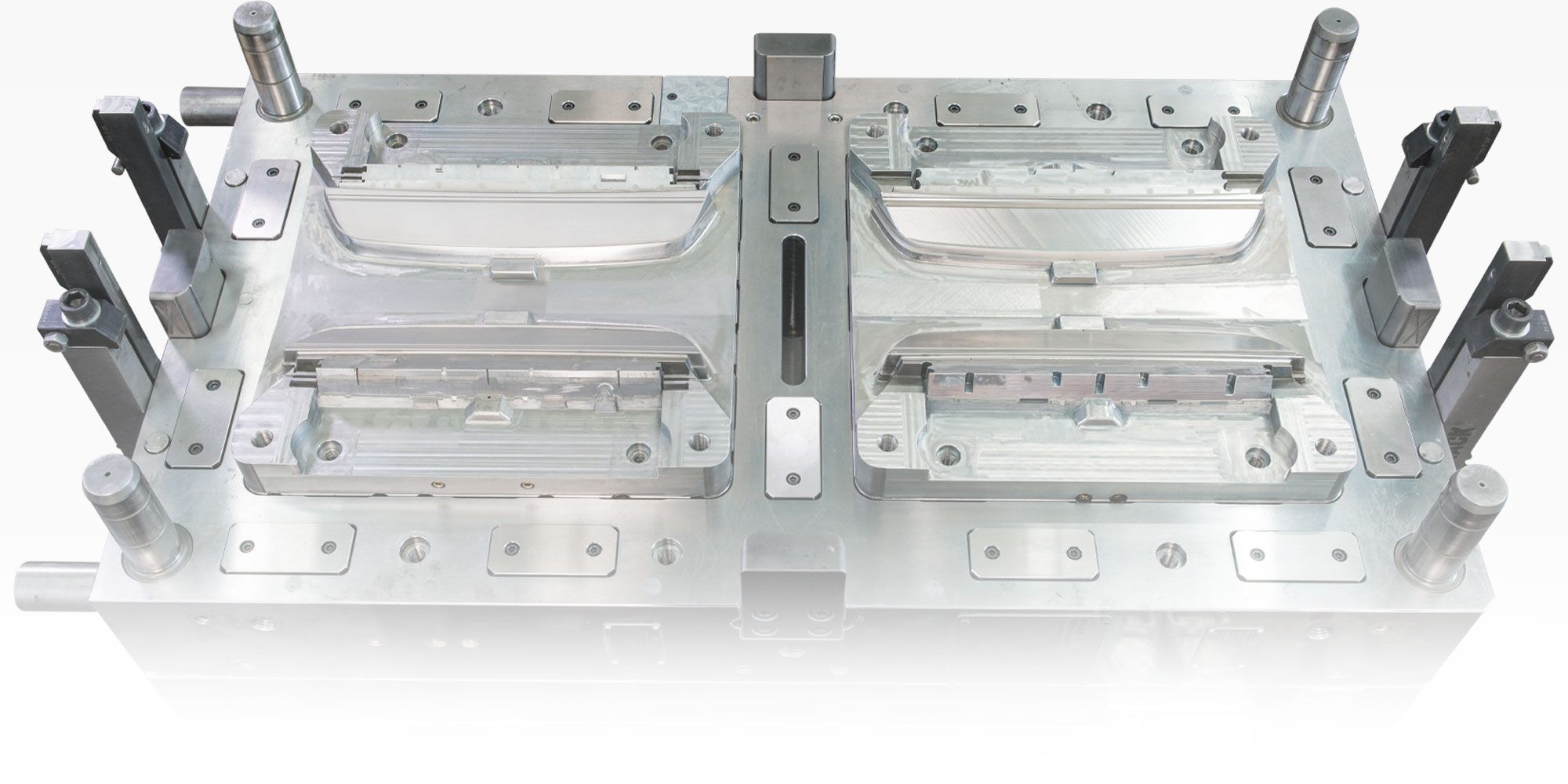

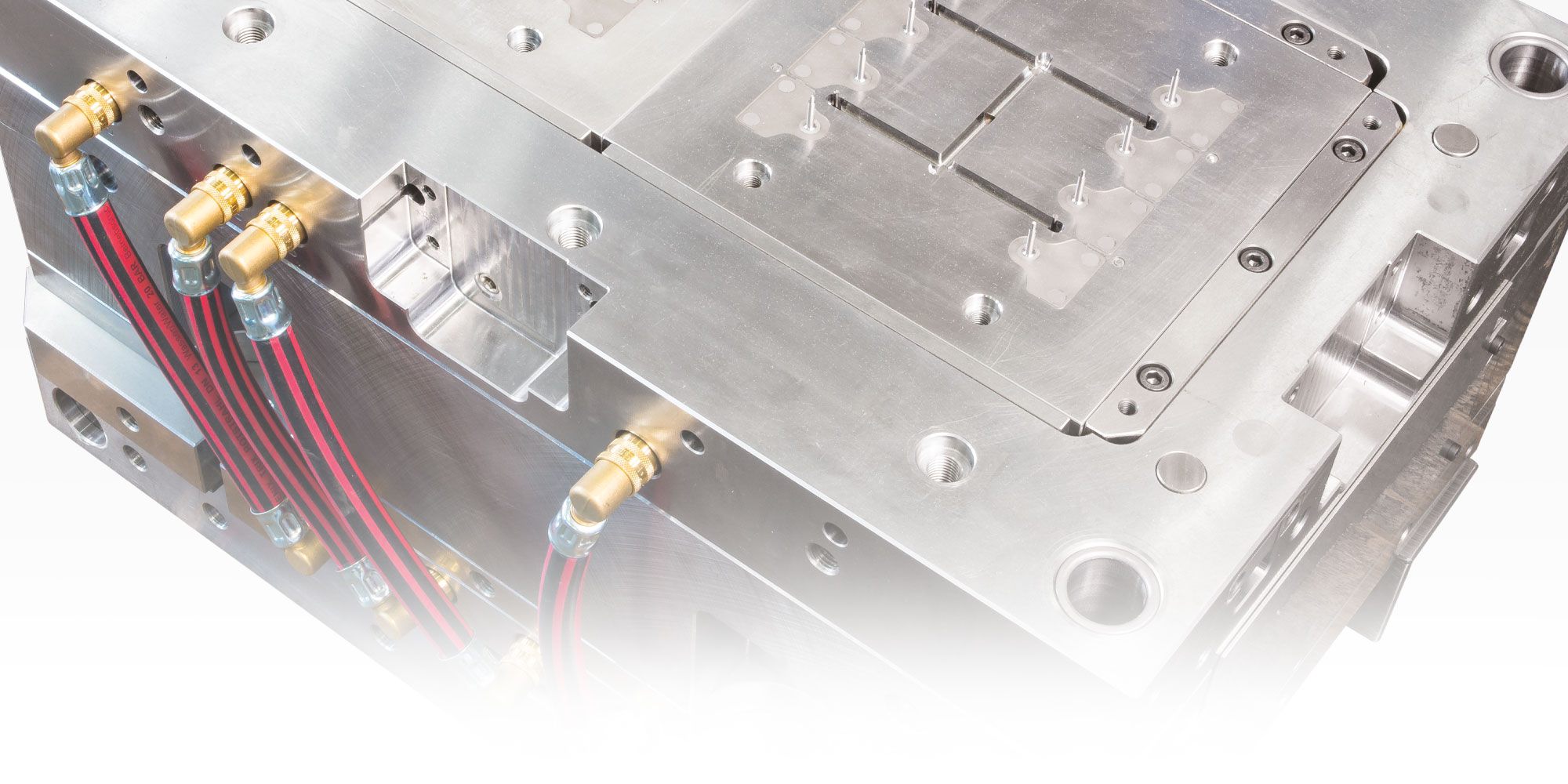

Pillar 2 of innovative toolmaking

Design & Development / Work Preparation

Design, development and construction are becoming increasingly complex and important as part of the toolmaking process.

We are committed to further developing and perfecting our knowledge and skills.

-

Design & Electrode Design

CATIA V5 R28 -

Fill simulation with CADMOULD 3D-F

-

CAM throughout with hyperMill