The 3 pillars of innovative toolmaking

The 3 pillars of innovative toolmaking

Formconsult news:

current trade fairs & lectures

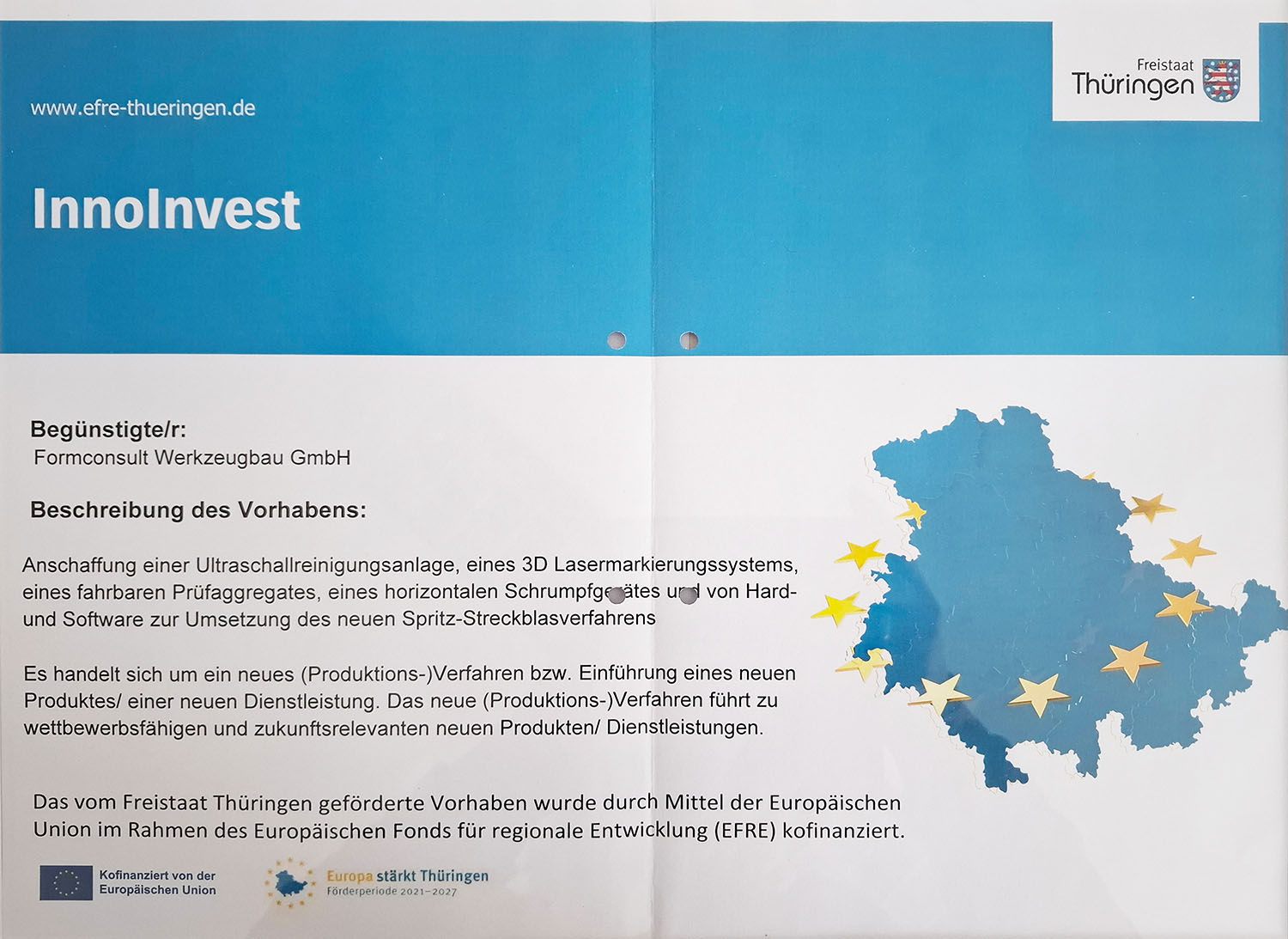

InnoInvest

Formconsult GmbH is investing specifically in state-of-the-art production and testing technologies as part of a new funding project. The acquisition of an ultrasonic cleaning system, a 3D laser marking system, a mobile testing unit, and a horizontal shrink-fit device, along with the integration of new hardware and software, will enable the introduction of an innovative injection stretch blow molding process.

With this, Formconsult expands its service portfolio to include a future-oriented production process and creates the basis for competitive, high-quality products and services with clear added value for customers and markets.

For over 50 years, the TecPart Innovation Award has recognized outstanding technical plastic products that excel through innovation, intelligent design, and sophisticated manufacturing.

This year, one of the eight awards presented at K 2025 in Düsseldorf went to electrical components manufacturer Wiska for the development of TriShot, the world's first cable gland manufactured entirely as a 3K injection-molded part. VDWF member Formconsult from Schmalkalden played a key role in the planning, implementation, and success of the project.

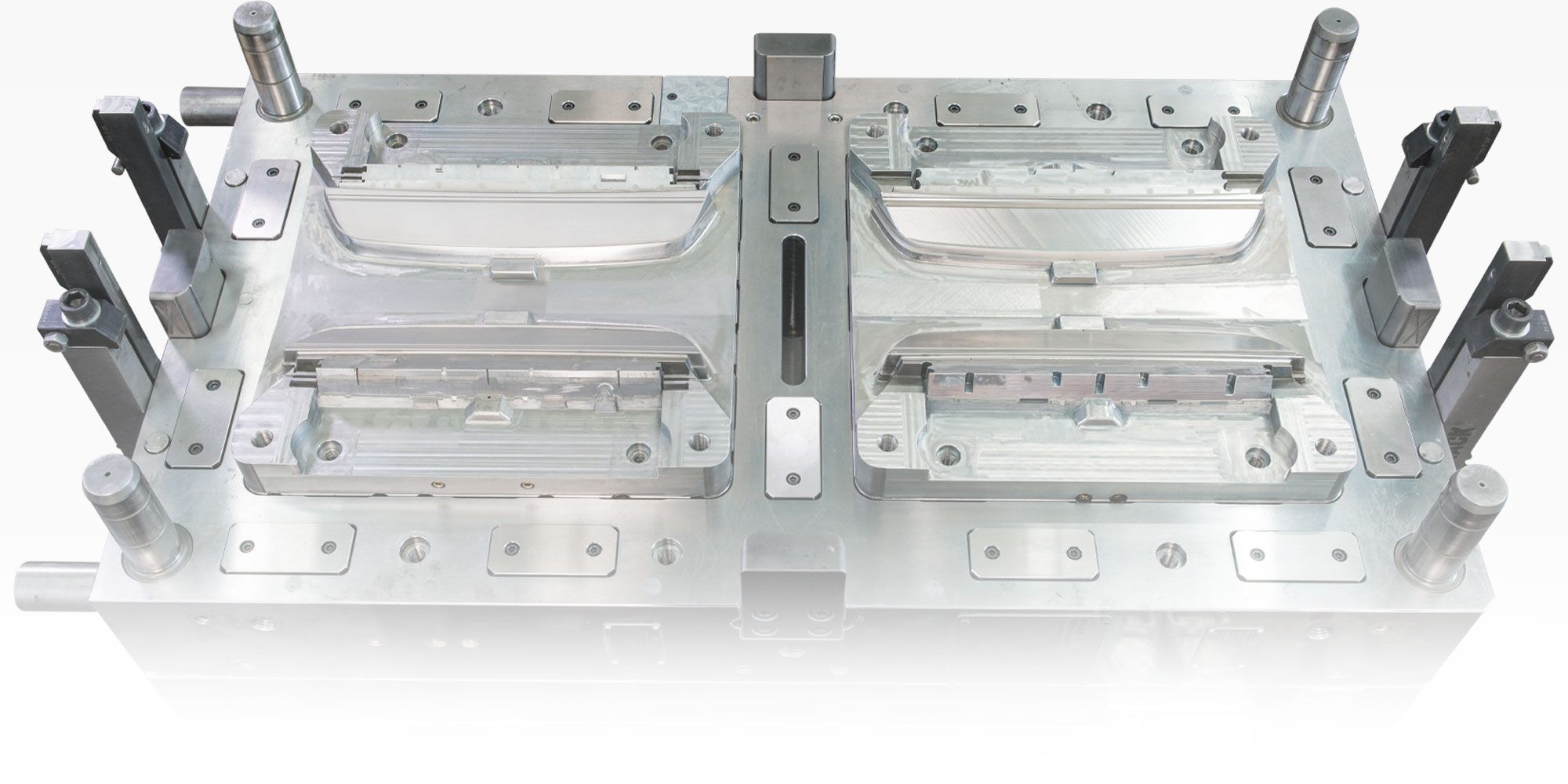

The development began with a trade fair contact and culminated in a synergistic process in which, for example, the material selection was jointly tested and defined to ensure proper adhesion and, through shrinkage, mobility of the components. The final result was a 3K mold with four stations and eight cavities that ejects fully functional components in a single pass – including seals and strain relief.

For Wiska, this meant not only more efficient production, but also high process reliability and independence from manual assembly. For us at Formconsult, the project was a confirmation of our innovative strength and that sometimes you just have to be in the right place at the right time with the right idea.

We congratulate our customer, the award-winning Wiska!

Markus Diegel honored

As part of the award ceremony for outstanding theses at Schmalkalden University of Applied Sciences by the VDWF, the young engineer Markus Diegel was honored - which was created in cooperation with Formconsult from Schmalkalden

On a high-tech tour in 'Schmalle'

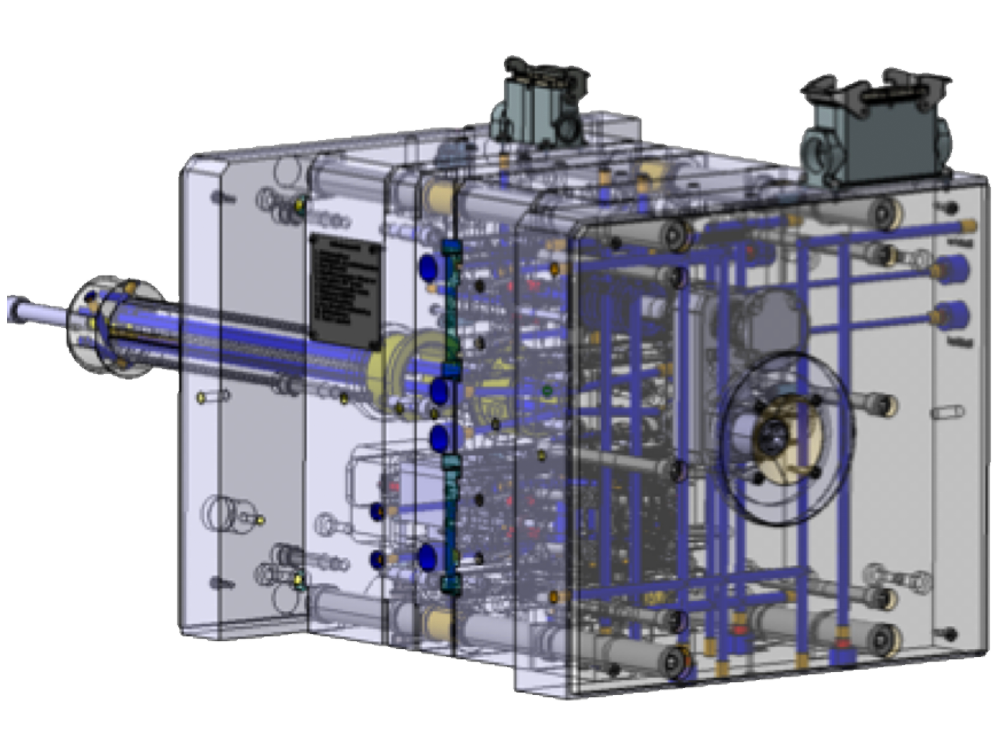

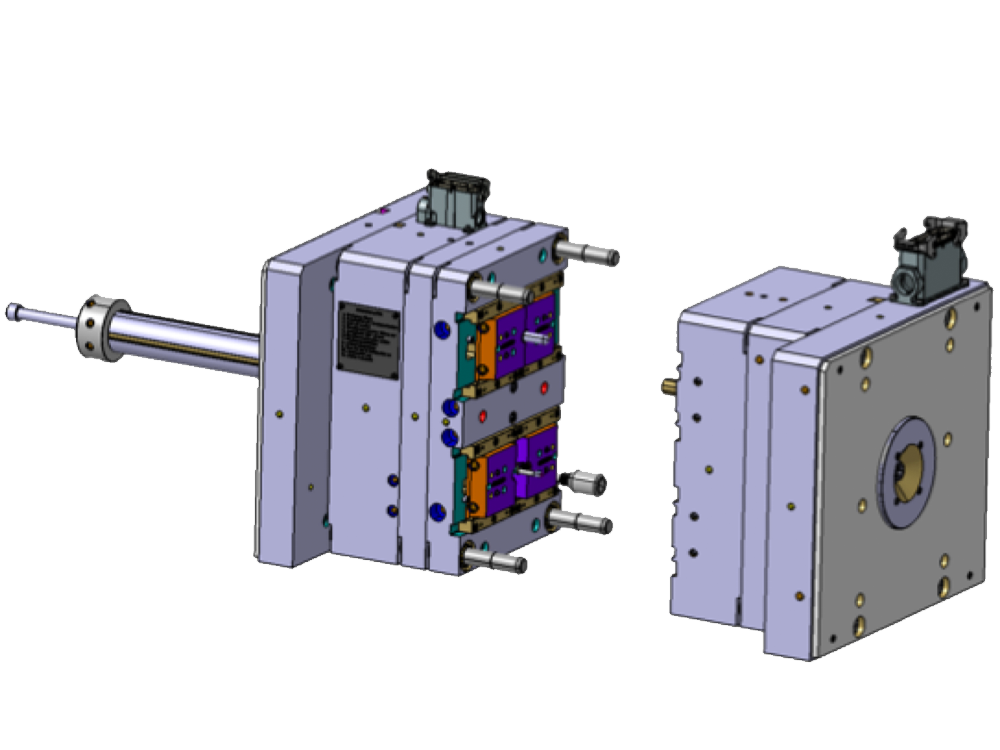

New & patent pending

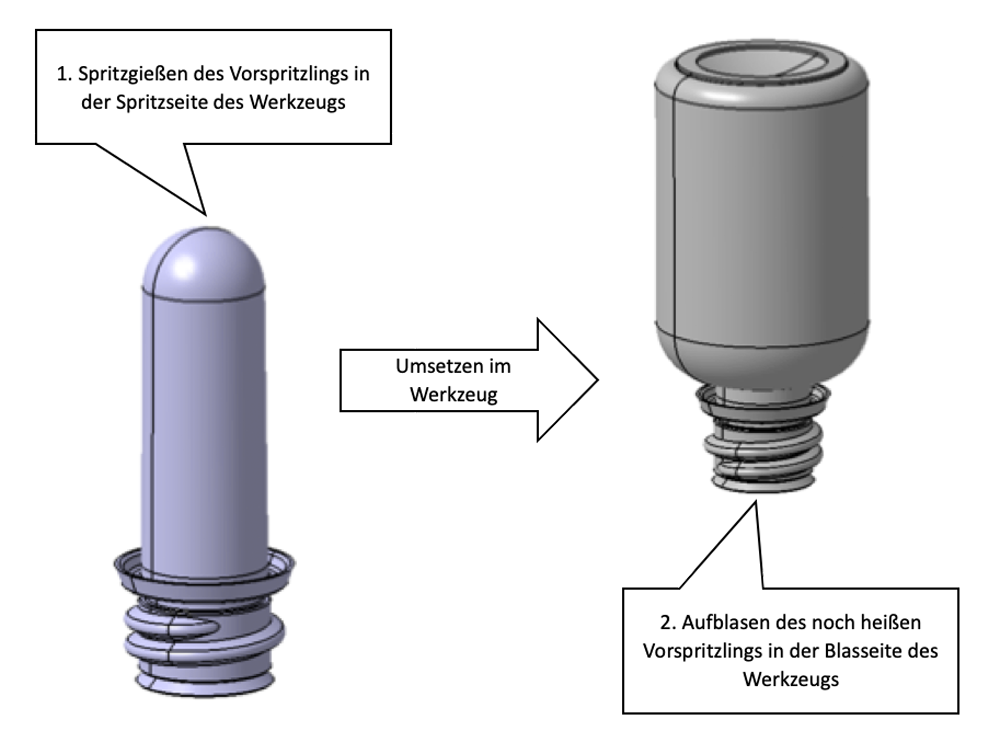

Splash-stretch bubbles

- Using a conventional 1K injection molding machine

- No hydraulic core pulls (oil) are necessary

- Drive with three-phase servo motor integrated into machine control

- An air pressure of approximately 8 bar is sufficient to inflate the bottles

- The blower unit is largely constructed from standard components

- Transferring the pre-molded parts to the blow molding side is done using an external slide on an index plate

- Manufacturing can take place in a cleanroom

- Removal of bottles from blow side using handling

- Bottle size 10 - 100 ml

- PET plastic, CBC, COC and COP

Support & promotion of startups

Supplements by & with - Tim Budesheim

The SUPPNIZER - a product created in cooperation between Formconsult Werkzeugbau GmbH and Tim Budesheim, a university graduate and bodybuilder from Schmalkalden: the Suppnizer, a supplement container for bodybuilding needs.

Trade Fairs & Lectures

May 13-15, 2025 KUTENO

Bad Salzuflen Exhibition Centre

Hall 20 | Booth 20 F 15

May 6th - 9th, 2025 Molding Expo

Stuttgart Trade Fair

Hall 6 | Booth 25A

March 13, 2025

28th Technology Day at the Brandboxx

Hannover / Langenhagen

February 25th and 26th, 2025 KPA

Plastic Products Currently

STAND 2-D"

15.10. - 19.10.2024 Fakuma

24.09.2024 VDWF/WBA Practical Forum Toolmaking

Presentation by Formconsult (Stephan Hoffmann) on the topic of “Innovative Toolmaking”

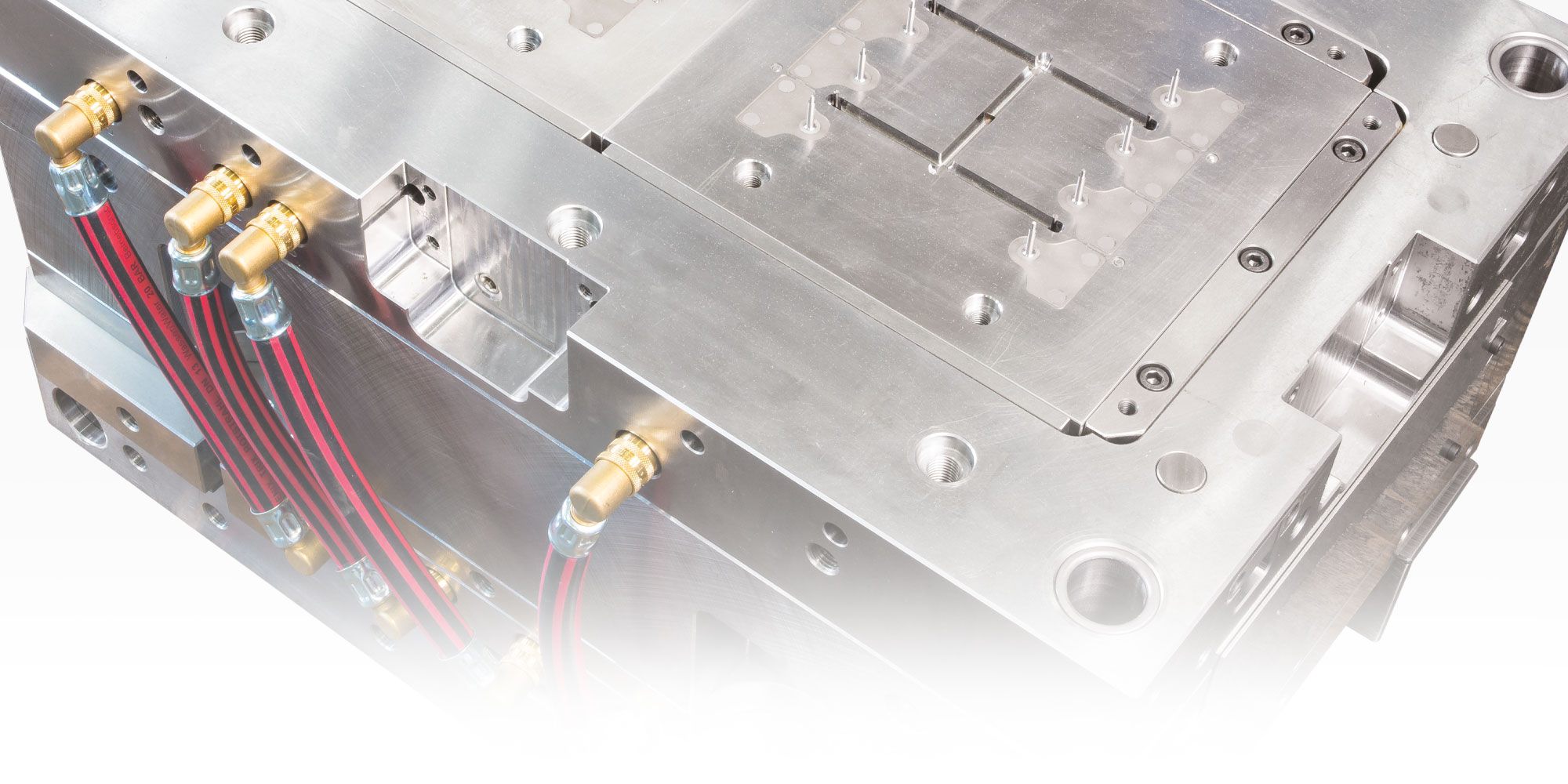

09/17/2024 Wednesday + temperature control forum

TEMPERATURE FORUM

Focus on: innovative temperature control concepts designed by: Formconsult Werkzeugbau GmbH & enesty GmbH